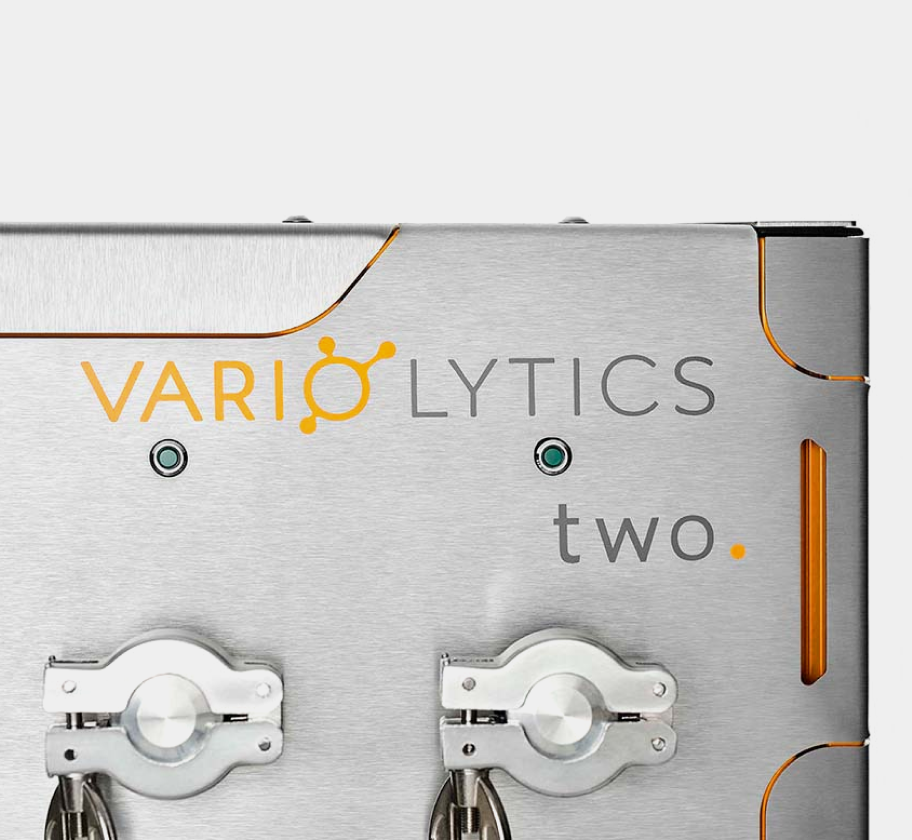

Vario two. | Liquid- and Gasanalyzer

Analysis Allrounder for simultaneous analysis of substances from liquids and gases

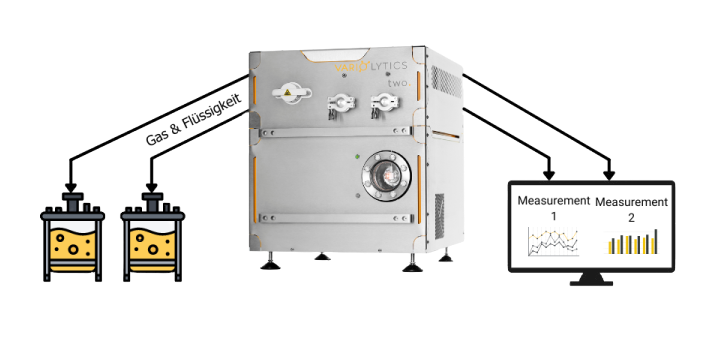

The Vario two. is the big brother of the Vario one. Our Allrounder is the world’s first mass spectrometer that can measure simultaneously from the liquid and gas phases. The liquid and gas analyzer is particularly used for fermentation monitoring and bioprocess engineering, but optimizes any processes in which parallel measurements from the liquid and gas phases are necessary. Simultaneous measurement from both liquid and gas dramatically increases the benefits of mass spectrometry relative to the initial cost. The combined liquid and gas measurement is patented by Variolytics and is not offered by any other supplier.

The Top 4 Advantages of the Analysis Allrounder

Gas and liquid

Designed to measure from multiple sources simultaneously using a multi-channel pump and new software architecture

Sensitive

High detection sensitivity from low ppb to 100% range

Multiparameter

Measures all volatile components simultaneously and without delay

Multiplexing

Designed to measure from multiple sources simultaneously using a multi-channel pump and new software architecture

Analysis Allrounder for Liquid and Gas Measurements

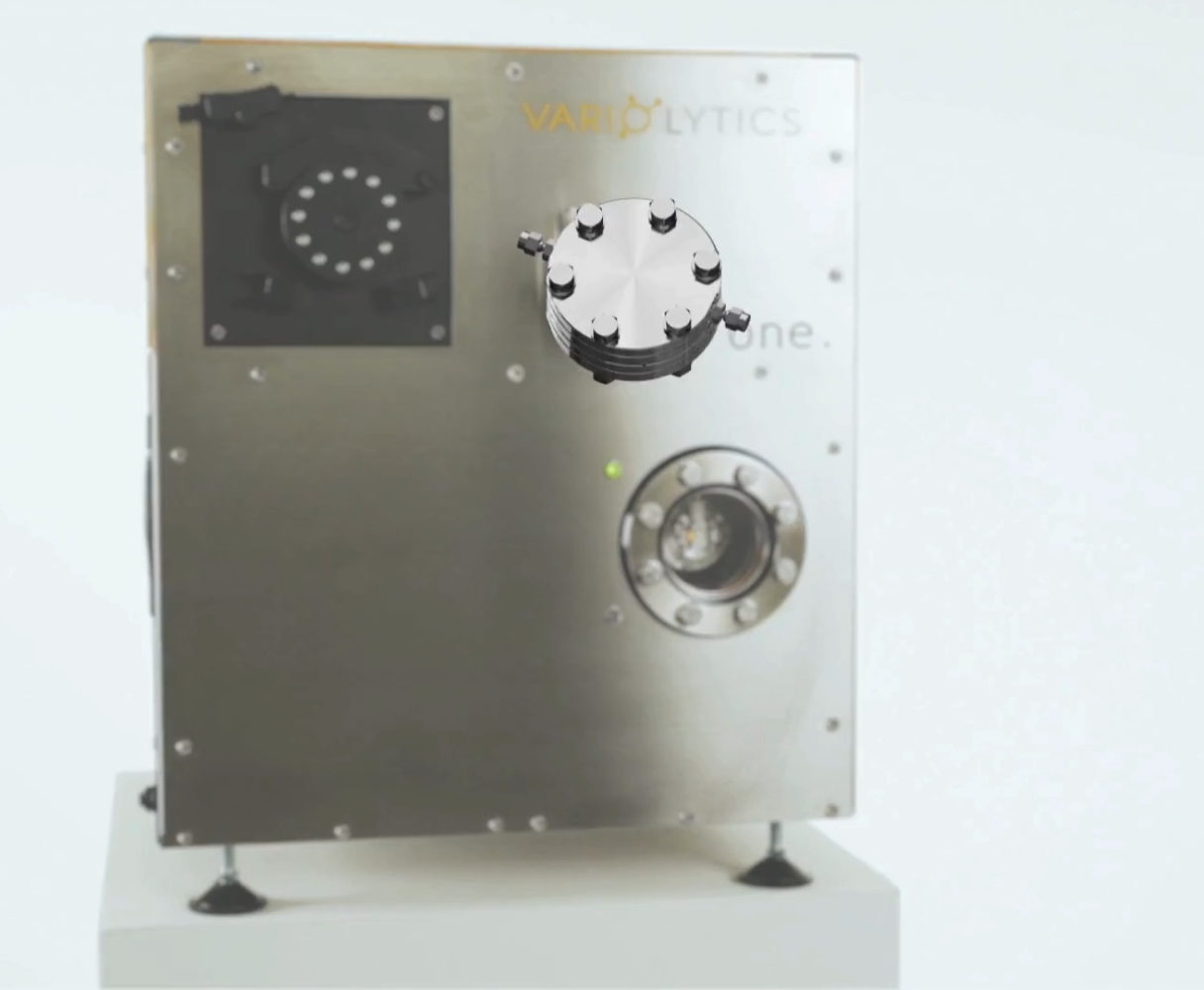

The Vario two. with its patented inlet system is designed to measure in parallel from the liquid and gas phases. The liquid and gas analyzer is the ideal combination of a classic quadrupole mass spectrometer for gas analysis and a membrane inlet mass spectrometer (MIMS technology) for liquid analysis. Since the Vario two. can be easily integrated into the industrial process, it measures permanently and without disturbing the process. The device provides consistently accurate measurement data with low measurement noise (low noise) and high linearity, allowing changes in responses to be tracked in real time (from 25 milliseconds). The Allrounder adapts perfectly to your individual application. For example, the volatility of substances in the sample stream can be increased by changing the temperature control of the membrane module.

User-Friendly Hardware and Software

The membrane inlets of the instrument allow online as well as inline measurements directly in the process, so that no sample preparation is necessary. This saves time and resources and allows to react quickly to changes in the process, thus optimizing it. The user-friendly software architecture simplifies real-time control of the machine and visualizes the measurement data in the same user interface. The hardware is modular – so the membrane module can be replaced and, for example, autoclaved in a single step.

The Ideal Inlet for your Measurement Task

The Variolytics membrane inlets allow stable multi-parameter measurements from the liquid. The membrane module contains a hydrophobic and organophobic membrane. At the interface of the membrane, volatile components present in the liquid are continuously transferred through the membrane into a vacuum. These parameters are then measured directly in the mass spectrometer. The membrane inlets are easy to autoclave and can be easily replaced if necessary.

Not sure which is the ideal inlet for your measuring task? Simply contact us and we will be happy to advise you.

Not sure which is the ideal inlet for your measuring task? Simply contact us and we will be happy to advise you.

Flow Cell

With the flow cell, processes can be monitored online. For this purpose, a bypass is laid from the reaction site to the flow cell. For this reason, no probes or other components need to be inserted directly into the process. Therefore, the process is not disturbed by the measurements. In addition, the module enables the measurement to be specifically influenced, for example, by setting a specific temperature or adding substances (e.g. acid to lower the pH).

In-Situ Sensor

With the in-situ sensor, measurements are made directly in the process, at the reaction site, and do not require a bypass. For this reason, the in-situ sensor has faster response times than the flow cell and therefore there is no time delay in the measurement. Processes in which very rapid changes occur can therefore be mapped in real-time using measurement technology. This membrane inlet is particularly suitable for measurements of dissolved gas concentrations.

Ideal for Multiplexing

… to measure from multiple sources simultaneously

Multiplexing allows customers to run multiple measurements on the same instrument. This allows different samples to be evaluated simultaneously. This leads to time savings in measurement tasks and reduces costs for expensive measurement technology. The Vario two. can also be easily integrated into a control system via our software. In biotechnology, two or even four bioreactors can thus be monitored and controlled simultaneously.

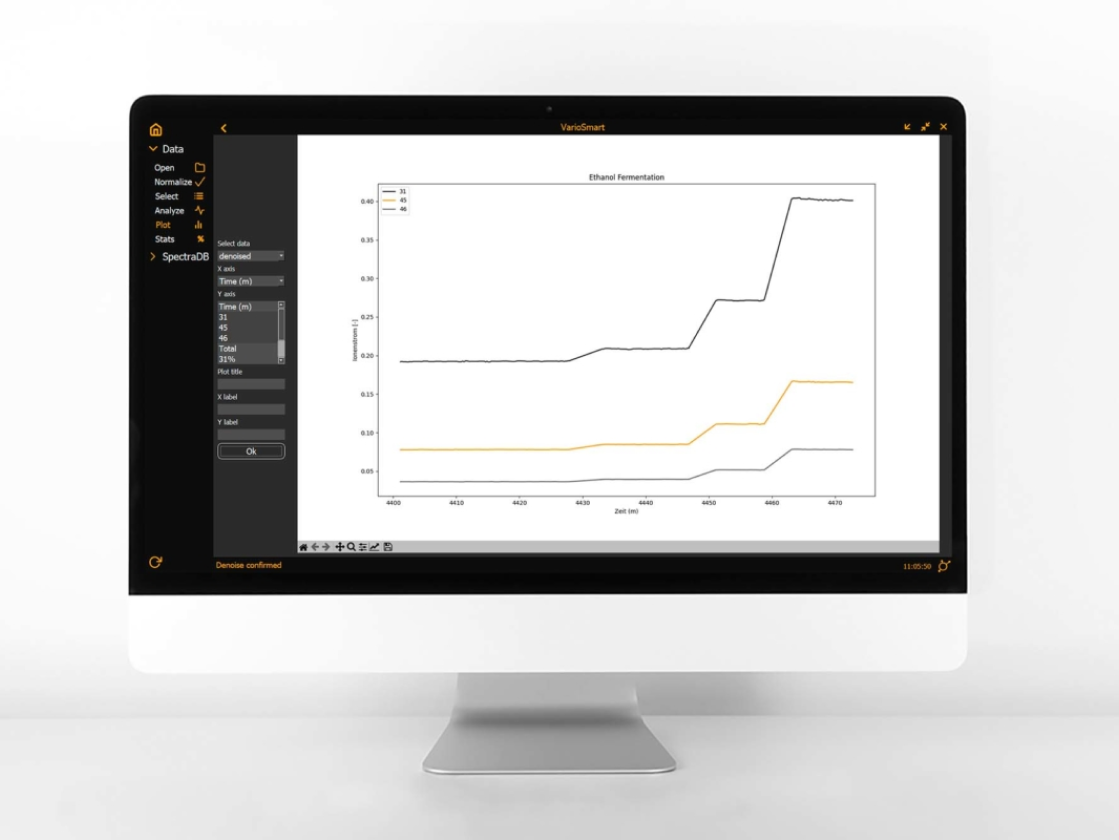

Latest Software Architecture

… for problem-free process integration

Tired of outdated software? So are we! The Vario two. offers a software architecture that can be easily integrated into process control systems or other hardware via common interfaces. A modern user interface and smart functions make it easy to use. Automated rotans even allow “stand-alone” operation for continuous measurements.