Trusted by

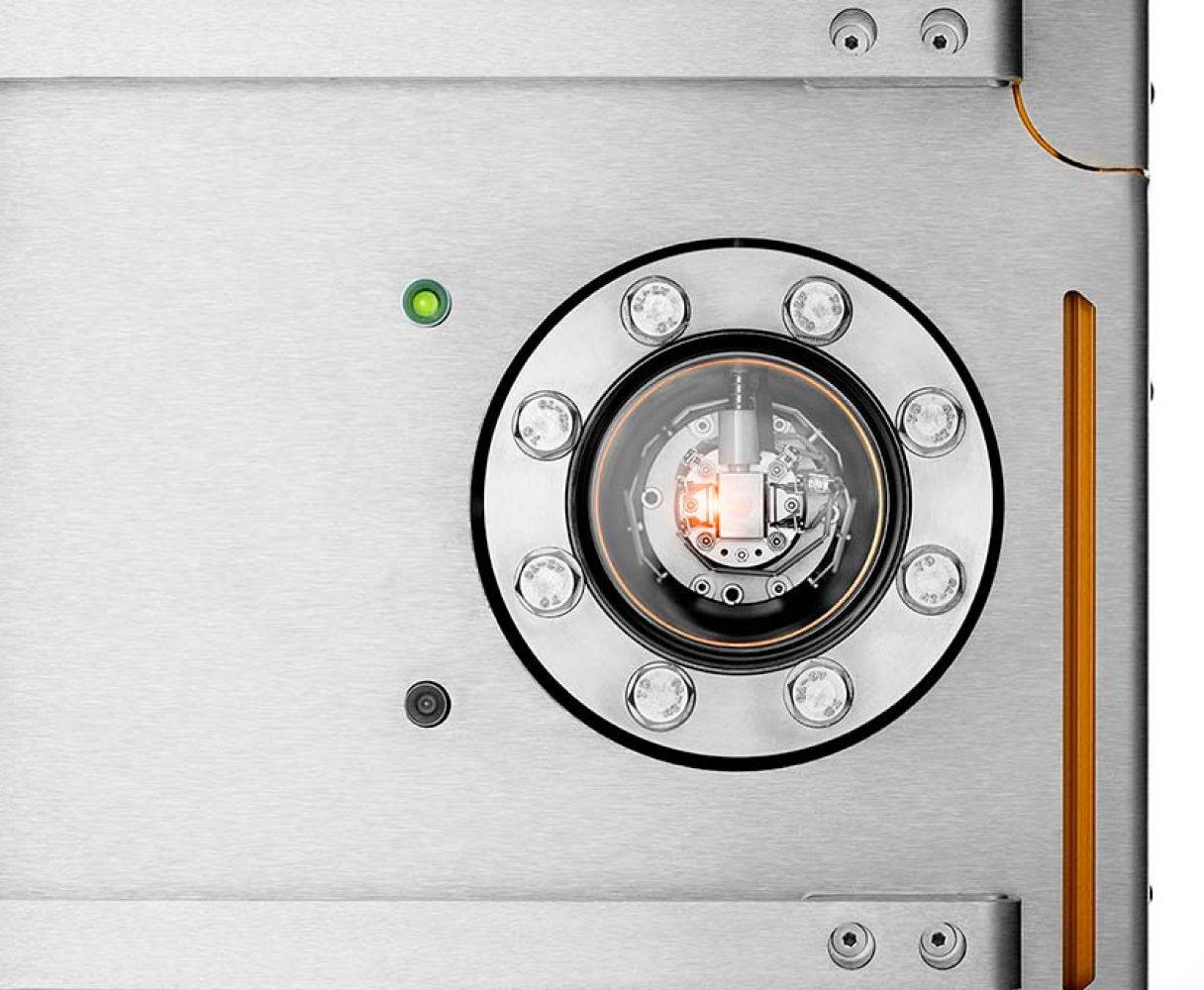

EmiCo. Our analyzer of greenhouse gases

(CO₂e)

at the same time

(KWh)

Why choose EmiCo?

Gas & Liquid Measurements

Simultaneous measurement of nitrous oxide (N₂O) and methane (CH₄) in the gas and liquid phase

Multiplexing

Measure up to eight aeration tanks simultaneously with one analyzer

Sensitive

Large measuring range, low detection limits from the ppb to the 100% range

No Drift

Auto-calibration with reference gas prevents drift in the measurement result from occurring

EmiCo Benefits

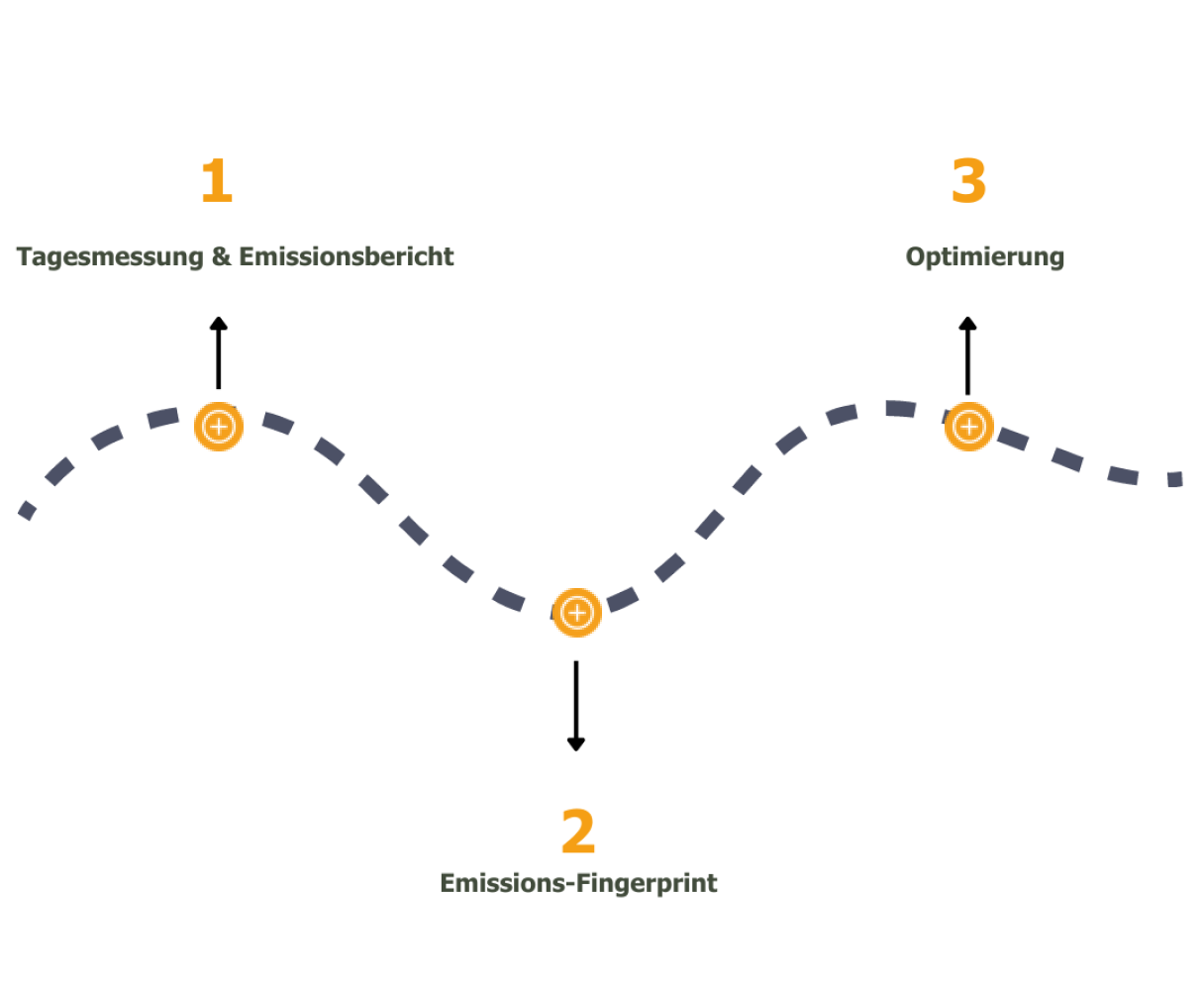

How do we optimize?

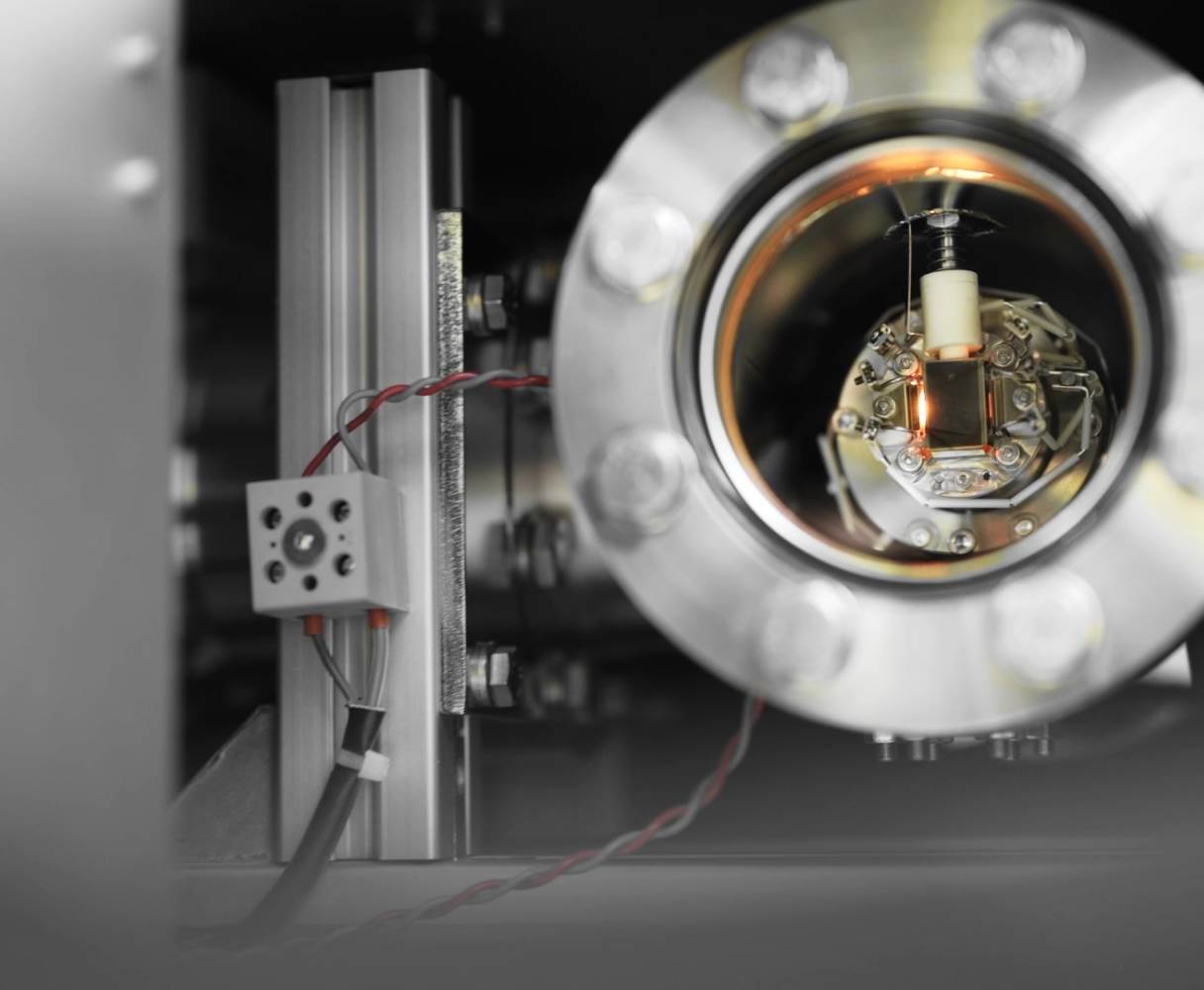

How does the technology work?

Mass-spectrometry-based analysis has a large measuring range, with low detection limits from the ppb to the 100% range. EmiCo provides multi-parameter measurements in real-time from the liquid & gas phase. EmiCo is calibrated to measure the following parameters, in relevant concentrations for emission control in wastewater:

» Nitrous oxide (N₂O) » Methane (CH₄) » Oxygen (O₂) » Carbon dioxide (CO₂) » Nitrogen (N₂)

Patented Inlet-System

… enables simultaneous liquid and gas measurements with mass spectrometry.

Your contribution is important!

EU-Goals and German Regulation

Reasons for achieving Net-Zero

Wastewater treatment plants are significant sources of greenhouse gas emissions, primarily methane and nitrous oxide. By implementing advanced technologies and efficient processes, we can substantially decrease these emissions . Moreover, emissions reduction at wastewater treatment plants is socially equitable. Water tariffs are typically structured so that everyone pays a similar rate, regardless of their income level. As a result, the burden of emission reduction is distributed fairly among the population. Unlike some climate mitigation strategies that require sacrifices or lifestyle changes, reducing emissions at wastewater treatment plants does not entail negative side effects on individual behaviour. Unlike needing to fly less or drastically alter daily habits, emissions reduction at these facilities can be achieved through technological advancements and process improvements.

Have we peaked your interest?

Then we look forward to hearing from you!

Customer Journey

Customer’s case is assessed and technical details clarified

1 day emission monitoring service and savings potential analysis

Details for purchase of EmiCo system are finalized and agreed upon

System is built according to customers’ needs and delivered according to the agreement

Site is prepared for installation. System is set-up & configured

Customer is trained to operate the system and understand outputs

EmiCo monitors treatment process and provides insights on direct emissions

EmiCo data is correlated with process values and optimization model is generated

Customer is provided with lifetime of support