Trusted by

What does the Emissions Monitoring Service offer?

Customer Journey

Customer’s case is assessed and technical details clarified

1 day emission monitoring service and savings potential analysis

Details for purchase of EmiCo system are finalized and agreed upon

System is built according to customers’ needs and delivered according to the agreement

Site is prepared for installation. System is set-up & configured

Customer is trained to operate the system and understand outputs

EmiCo monitors treatment process and provides insights on direct emissions

EmiCo data is correlated with process values and optimization model is generated

Customer is provided with lifetime of support

How does it work?

Mobile Analysis Unit

Our measurements are provided through a mobile analysis unit (mass-spectrometer) housed in a specially equipped vehicle. The vehicle is positioned near the aeration basins. From the measuring spot at the basin, a probe line delivers the sample to the analyser in the vehicle. This set-up enables flexible real-time measurements of emissions at wastewater treatment plants.

Hood And Sample Line

A hood is connected to the EmiCo system via a 100-metre sample line. The hood is positioned on the surface of the aeration basin and captures the exhaust air. Our in-situ probe is placed under the hood and provides liquid phase measurements. By changing the position of the hood at different points in the biological step, customers receive a broad overview of their emissions.

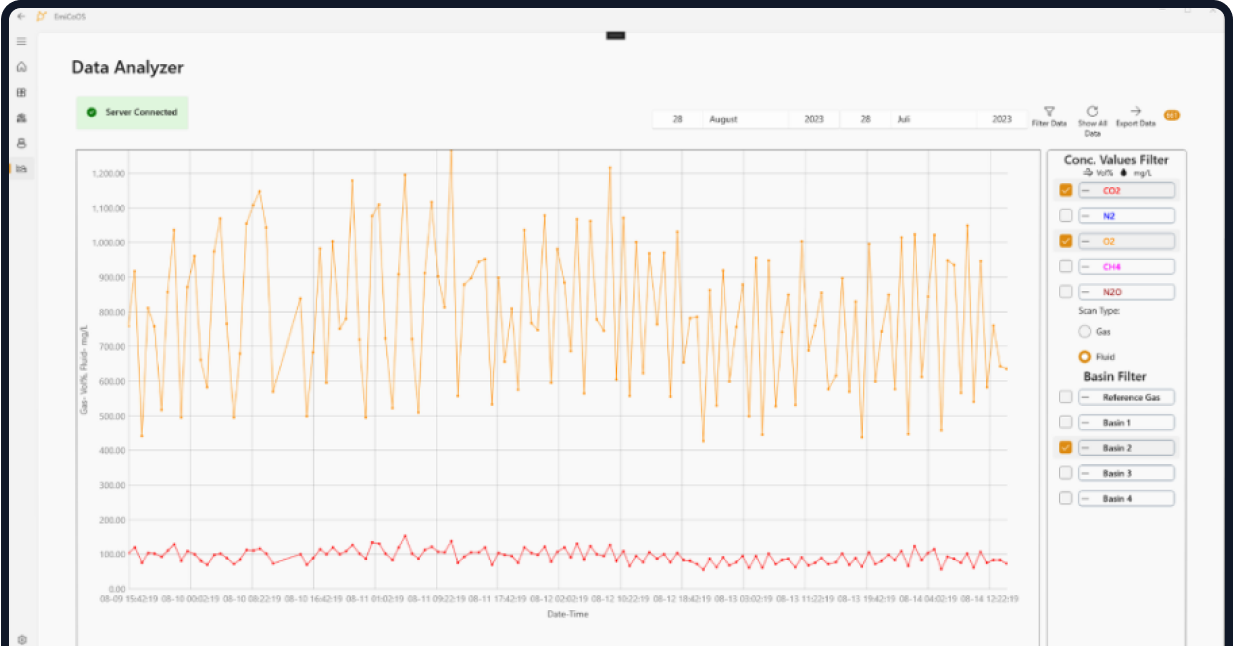

Emission Rates

In addition to analysing the concentrations of N₂O and CH₄ from the liquid and gas phase, temperature and flow of the exhaust gas is measured, as well as O₂ and CO₂. This provides precise insights into the formation, elimination and emission rates and gives customers additional information that can help optimise their plant.

Emissions Report

After the test measurements are completed, customers will receive a detailed emissions report, as well as a comprehensive method statement of the analysis. This report contains important information such as the CO₂ footprint and the emission factor of the wastewater treatment plant. This data will help customers take targeted measures to reduce emissions and reach net-zero.

What can be measured?

Benefits of the Emissions Monitoring Service

Our pricing package includes

The emissions report is a comprehensive analysis of the monitored results and your organization’s environmental performance.